What are concrete pump piping accessories?

concrete pump piping accessories is a general term for all kinds of components connecting the conveying piping system between the concrete pump and the pouring point, constituting a complete concrete conveying channel. These accessories play a vital role in concrete pumping construction, directly affecting the pumping efficiency, construction quality and equipment life. High-quality piping accessories can ensure the smooth flow of concrete under high pressure, reduce the risk of pipe blockage, while withstanding the wear and tear of concrete and pumping pressure.

In modern building construction, especially in high-rise buildings, large infrastructure projects, concrete pump pipe fittings have become indispensable construction components. They not only improve the construction efficiency, but also make the concrete pouring more accurate and even, greatly improving the quality of the project.

Main types of concrete pump piping accessories

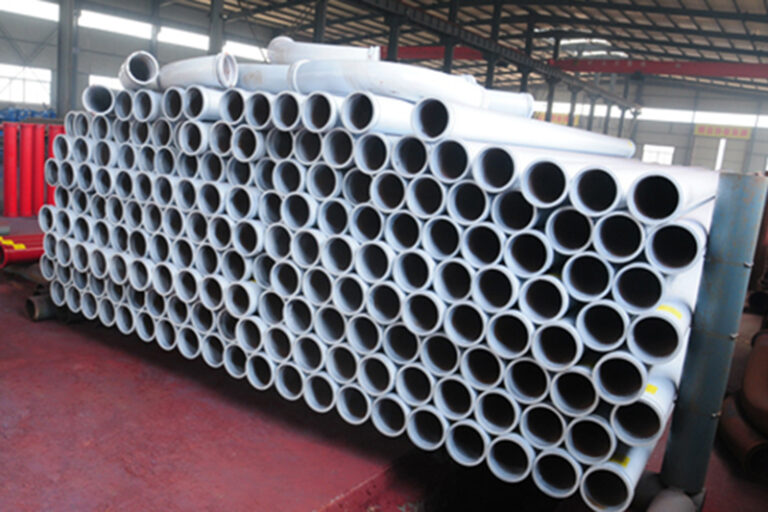

- Straight pipe

Straight pipe is the most basic component in concrete pumping system, usually a standard length of steel pipe (common 3-meter specification), which is responsible for the main conveying task of concrete. High-quality straight pipes are made of wear-resistant alloy steel with specially treated inner walls to resist concrete abrasion. The ends of the straight pipe are fitted with precision machined flanges to ensure tightness and coaxiality of the connection. - Elbow

Pipe elbow is used to change the direction of concrete transportation, and the common angles are 90°, 45°, 30°, 15° and other different specifications. Elbows are the most abrasive part of the piping system, so high-end elbows are often double-layered or rotatable in order to adjust their position after wear and tear to extend their service life. Special projects may also need to customize the angle of the bend to meet the needs of complex construction. - Pipe Clamps and Flanges

Pipe clamps (also known as pipe clamps) and flanges are key components of pipe connections, ensuring that sections of pipe are tightly and securely joined together. High-quality pipe clamps are made of high-strength steel with rubber seals to prevent slurry leakage. Flanges are welded to the end of each pipe section and bolted to the adjacent pipe. Modern quick-connect systems greatly improve the efficiency of pipe assembly. - Reducers

Reducers are used to connect pipes of different diameters to achieve a smooth transition in the pumping cross-section and to avoid the risk of plugging due to sudden changes in cross-section. Common combinations of reducers include 125mm-150mm, etc. The design adopts a gradual change in structure to reduce the resistance of concrete flow. - Hoses

Pumping hose are usually installed at the end of the delivery pipe to give greater flexibility in the pouring operation. High-quality rubber hoses are embedded with steel wire reinforcement to maintain flexibility and withstand pumping pressure. The length of the hose is usually 3-6 meters, and longer sizes can be customized in special cases. - Other special accessories for concrete pump pipeline

Shut-off valve: used to temporarily block the flow of concrete, to facilitate the handling of pipe blockage or replacement of pipeline.Cleaning ball: a necessary tool for pipe cleaning, used with water or compressed air

Selection and Maintenance Points of concrete pump piping accessories

When choosing the concrete pump piping fittings, it is necessary to consider the characteristics of the project, the parameters of the concrete performance and the pumping pressure, and other factors. Although the initial investment in high-quality fittings is high, it can reduce the frequency of replacement and maintenance costs in the long run. In daily use, fittings should be regularly checked for wear and tear, especially the bends and straight pipe ends and other vulnerable parts, to establish a perfect management file of fittings to ensure construction safety and efficiency.

With the development of construction technology, concrete pump piping accessories are also constantly innovating, such as intelligent wear monitoring system, super wear-resistant composite materials and other new technologies, is promoting the development of this field in the direction of more efficient and durable.