How to lay the concrete pump pipe line

Concrete pump pipe laying guide: scientific installation to ensure construction efficiency

As a concrete pump pipe manufacturer, we know that the standardization of pump pipe laying has a direct impact on concrete conveying efficiency and construction safety. Reasonable laying not only reduces the risk of pipe blockage, but also extends the service life of the pipe. The following are the key steps and precautions for professional laying of concrete pump pipe:

First, laying concrete pump pipe of the preliminary preparatory work

Pipe inspection

The quality of the pump pipe needs to be checked one by one before installation to ensure that there are no cracks, deformation or wear on the inner wall, and the flange bolt holes should be intact. The new pipe should be cleaned of antirust coating, and the old pipe should be cleaned of residual concrete.

Planning route

Design the pumping path according to the layout of the construction site, give priority to straight line and short distance programs, and reduce the number of elbows (it is recommended that the angle of the elbow does not exceed 90°). Avoid sharp turns or arrangements with too large a difference in height.

Second, concrete pump pipe laying steps

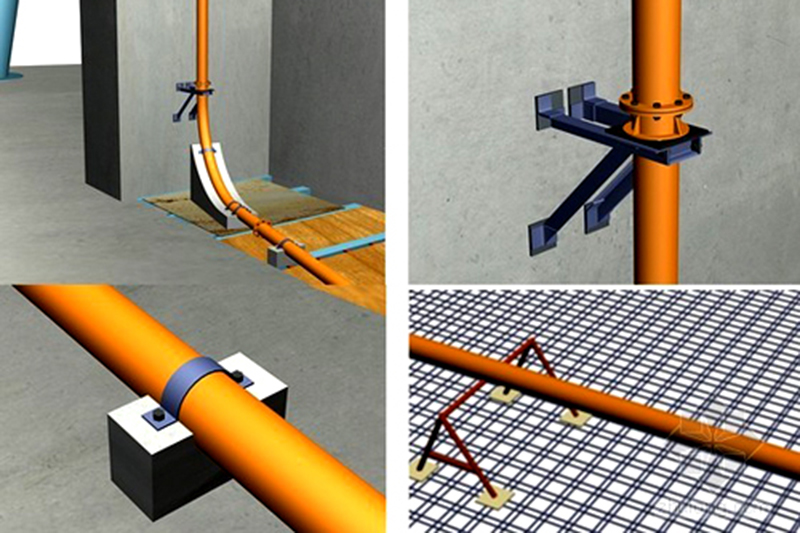

Foundation fixing

Horizontal section: every 3 meters set bracket or horse stool support, pipe hanging section need to add cushion wood square buffer vibration.

Vertical section: must be fixed with embedded parts or steel frame, each section of pipe at least 1 fixed point, high-level construction in the middle of the floor need to add buffer bends.

Pipe connection

Flange butt joints need to be installed with sealing rings, bolts need to be tightened diagonally to ensure that the force is uniform.

Additional reinforcement is required at the bend to avoid displacement due to pumping pressure.

Outlet and end arrangement

The length of the end hose is recommended to be no more than 3 meters, and avoid bending and folding.

The outlet should be perpendicular to the pouring surface, and the height of the free section should not exceed 2 meters to prevent aggregate separation.

Third. Key considerations for laying concrete pump hose

Safety Protection

When pumping at high pressure, it is forbidden to stand within 5 meters of the pipeline to prevent bursting and injury.

Cover the pipeline in summer construction to avoid the high temperature leading to concrete quick-consolidation pipe plugging.

Reduce the risk of pipe blockage

Use mortar to lubricate the pipeline before pumping, and clean the pipeline after stopping work for more than 30 minutes.

Control the aggregate size (not more than 1/3 of the pipe diameter) and slump (recommended 120-180mm).

Maintenance and dismantling

Flush the pipe immediately after pumping, and mark the pipe sections in order when disassembling for next use.

Regularly check the bends, reducers and other wear parts, wear more than 1/3 of the original thickness needs to be replaced.

Fourth, laying the common problems of concrete pump pipe solutions

Plugging treatment: Immediately counter-pump 2-3 times, invalid when the need for segmented investigation to clear the blockage.

Leakage treatment: replace the sealing ring or tighten the bolt after stopping the machine, and prohibit operation under pressure.

Scientific pumping pipe laying can improve pumping efficiency by more than 30% and significantly reduce the failure rate. As a professional manufacturer, we recommend using high manganese steel wear-resistant pipes (with a life span of more than 50,000 cubic meters) and double-layer hydraulic sealing flanges to cope with the demands of high-intensity construction.