the ultimate guide to concrete pump pipe efficiency

Concrete pump pipe is a key component in the concrete delivery system, and its proper use and maintenance directly affects the construction efficiency and cost. As a professional supplier of concrete pump fittings, we provide you with this ultimate guide to help you optimize the operation process and extend the life of concrete pump pipe.

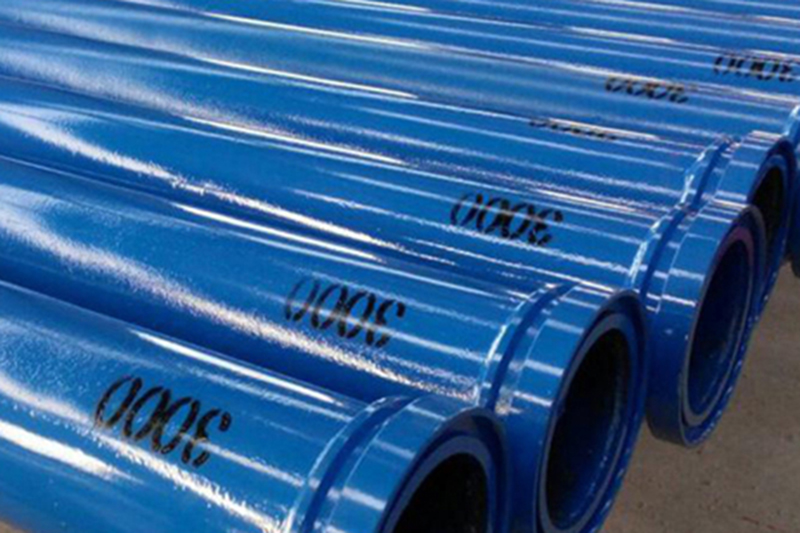

Choose the right concrete pump pipe

Material selection: common pump pipe materials include wear-resistant alloy steel and high-chromium cast iron, and double-layer wear-resistant pump pipe is recommended for high-wear environments.

Pipe diameter matching: according to the conveying capacity of the concrete pump and aggregate particle size to choose the appropriate pipe diameter (such as 125mm or 150mm), to avoid clogging or insufficient pressure.

Length design: Reasonably arrange the length of the pipe and the number of elbows to reduce the pressure loss, and it is recommended that the angle of the elbow should not exceed 90°.

Correct installation and connection

Sealability check: Make sure the pipe fittings interface is clean before installation, use special sealing ring or rubber gasket to prevent slurry leakage.

Fixing firmly: the pipes must be fixed with pipe clamps or brackets to avoid shifting or loosening caused by vibration.

Avoid sharp bends: keep smooth transition at the elbow to reduce the resistance of concrete flow and reduce the risk of wear and tear.

Key points of pumping operation

Pipe wetting: Use mortar or lubricant to wet the pipe before pumping to reduce the friction between concrete and pipe wall.

Control pump pressure: adjust the pumping pressure according to the conveying distance to avoid high pressure resulting in pipe burst.

Uniform conveying: keep the slump of concrete stable to avoid pipe blockage caused by fast or slow.

Daily maintenance and repair

Timely cleaning: rinse the pipeline with water immediately after pumping to prevent the concrete from solidifying and clogging.

Regular inspection: check the wear and tear of the pipes every week, focusing on elbows and connections, and replace them in time when they are found to be worn out.

Store dry: Idle pumping pipe should be stored in a dry and ventilated place to avoid rust and corrosion.

Common problems and solutions

Plugged pipe response: Immediately reverse pumping to pump back the concrete, disassemble the blocked section to clean up, avoid forced pumping.

Slurry leakage response: stop the machine to check whether the seal is aging or the interface is loose, replace the damaged parts.

Abnormal wear: If the local wear is too fast, check whether the installation of pump pipe is tilted or whether the concrete proportion is reasonable.

Correct use and maintenance of concrete pump pipe can not only improve construction efficiency, but also significantly reduce replacement costs. Choosing a quality pump pipe product and following the above guidelines will ensure that your project runs smoothly.