what are the benefits of using concrete pump pipes?

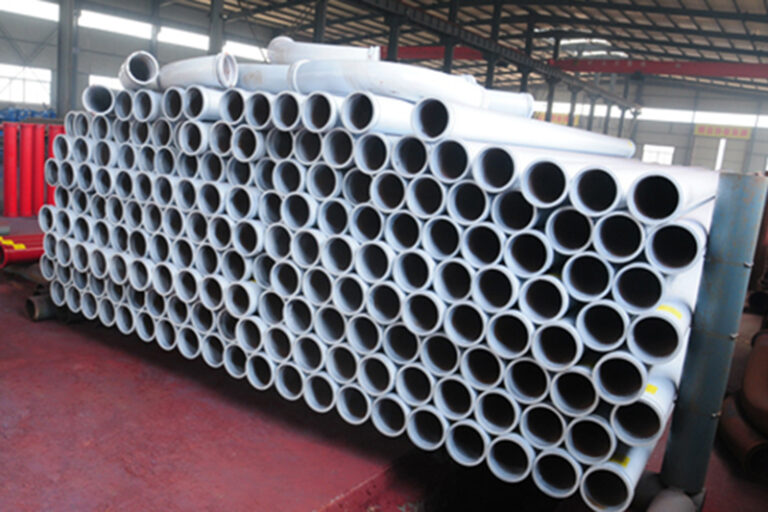

In modern building construction, concrete pump pipe, as an important delivery channel connecting the concrete pump and the pouring point, has become an indispensable key component for all kinds of projects. As a professional supplier of concrete pump pipe fittings, we are well aware of the important impact of high-quality pump pipe systems on project efficiency and quality. Below are five significant advantages of using high-quality concrete pump pipe:

Dramatically improve construction efficiency

Concrete pump pipe system can realize rapid and continuous conveying of concrete, which can increase the efficiency by 5-8 times compared with the traditional manual transportation method. Through the pump pipe transportation, the concrete can reach the high-rise or long-distance work surface in a short time, significantly shortening the construction period. Especially in high-rise buildings, large-scale infrastructure projects, the pumping pipe system can overcome the difficulties of vertical transportation, and realize the efficient operation of conveying 60-120 cubic meters of concrete per hour.

Ensure stable concrete quality

High-quality concrete pump pipe with smooth inner wall is made of wear-resistant alloy steel, which can effectively reduce the resistance during transportation and prevent concrete segregation and slump loss. Compared with the traditional way of multiple transshipment, the pump pipe conveys in one place, avoiding the separation of materials caused by multiple loading and unloading, ensuring the uniformity and strength stability of concrete, and ultimately improving the overall quality of the building structure.

Reduce labor cost and labor intensity

The use of pumping pipe system can reduce more than 60% of the concrete transportation labor requirements, significantly reducing labor costs. At the same time, it completely changed the heavy work mode of workers’ shoulder picking and hand lifting, reduced labor intensity and improved construction safety. In today’s rising labor costs, this advantage is particularly prominent, saving a lot of labor expenses for the project.

Adaptation to complex construction environment

Modern concrete pumping pipe system has strong environmental adaptability. Through the combination of pipe fittings of different lengths and angles, it can flexibly cope with a variety of complex construction scenarios: whether it is the vertical pumping of ultra-high-rise buildings or the long-distance horizontal conveying of underground projects; whether it is the bending arrangement of narrow spaces or the pouring needs of large-span structures, the pumping pipe system can provide the perfect solution.

Remarkable economic benefits

Although the initial investment is relatively high, the service life of high-quality concrete pumping pipe can reach 30,000-50,000 cubic meters of conveying capacity, and the long-term use cost is extremely low. Its wear-resistant, pressure-resistant, impact-resistant characteristics reduce the frequency of replacement, coupled with improved construction efficiency and quality, the overall economic benefits are very significant. According to statistics, projects using pump pipe system can save 15%-25% of the total project cost.

As a professional supplier of concrete pump fittings, we offer a wide range of high-quality pump pipes from 125mm to 250mm, all of which have passed strict quality tests and have excellent abrasion resistance and sealing properties. By choosing our pump pipe system, you will get more efficient construction experience, more reliable quality assurance and more comprehensive technical support services, creating more value for your project.